Other Systems

Other Systems

01

Packing Areas

Carton flow systems are ideal for high-volume packing zones, keeping items constantly available at the front. They minimize movement, reduce preparation time, and increase order efficiency.

02

Picking Lines

These systems optimize manual picking processes by maintaining product visibility and rotation. Operators work faster and more accurately, achieving better flow and warehouse organization.

03

Assembly Lines

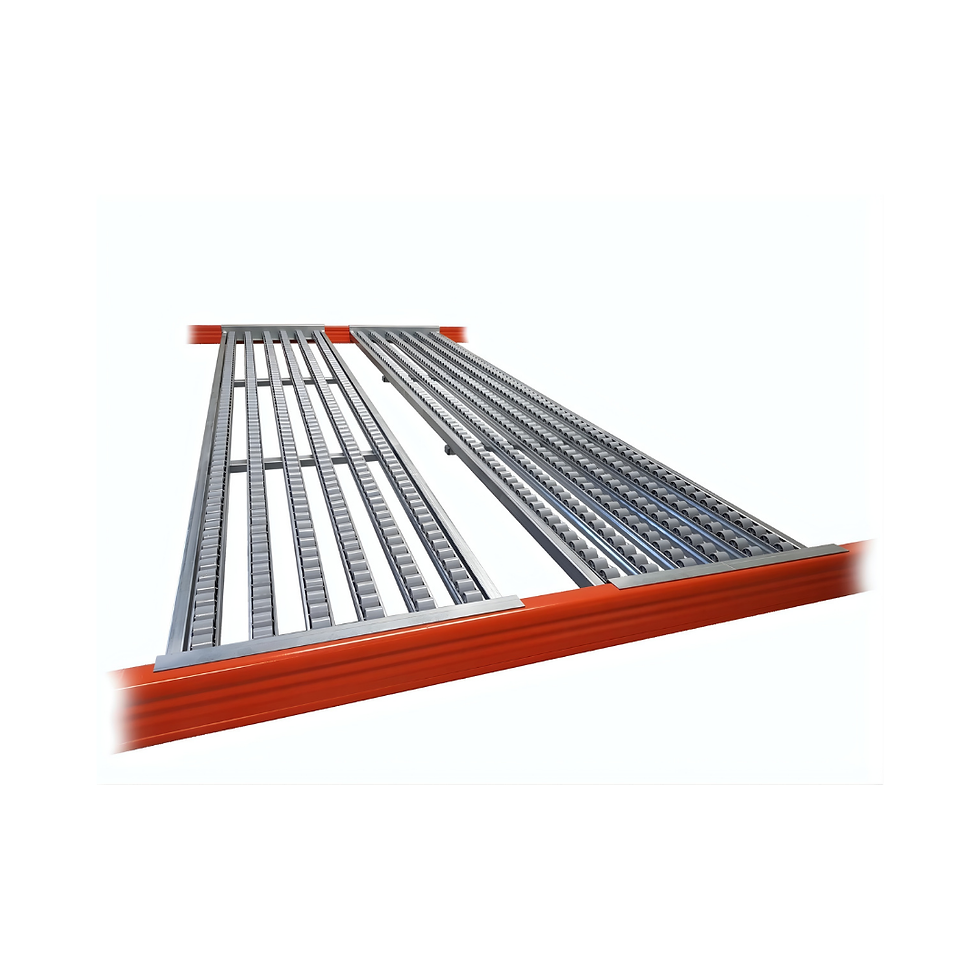

Integrated carton flow rails supply materials directly to production points. Their smooth gravity design supports continuous movement, improving balance and consistency in every operation.

Durable Carton Flow rails, premium quality and proven cost efficiency.

Your reliable supplier across America and Europe—Download our carton flow brochure, then schedule a quick consult for a tailored solution.

01

Onsite - Tech Support

02

Quality & Innovation

03

Warranty Included

04

Fast & Free Shipping

Let’s Talk

33 3880 3128

(+52) 444 130 0579

Visit Us

Benefits

75%

Labor Cost Reduction

Carton flow systems can reduce labor expenses by up to 75% by minimizing walking distances, order picking routes, and unnecessary product handling. With gravity feeding items to the front, workers spend less time searching or restocking, which increases overall warehouse efficiency and reduces operational costs.

50%

More Storage Utilization

Compared to static shelving, carton flow racking can improve usable storage space by as much as 50%. The system’s inclined design and continuous product rotation allow better density and organization, making every square meter of the warehouse more productive and accessible.

60%

Faster Order Picking

By keeping products automatically positioned at the front of the rack, carton flow systems speed up picking operations by 30% to 60%. The streamlined workflow reduces operator travel time, boosts accuracy, and helps companies handle higher order volumes without expanding their workforce.